Precision Fabrication Machinery Vancouver Wa

We sell only the highest quality metal fabrication machinery.

We can provide customers with build to print services for equipment, systems and assemblies.

We have many strengths, but two things make us stand out. Firstly, we do not accept sub-par quality. We expect the same from our suppliers. Many shops promise high quality, but very few deliver. Our process controls are key to making a difference. Secondly, our commitments to customers are a reflection of how we care. GSS Machinery holds integrity as a core value. Trust, hard work, reliability are the foundations of partnerships.

You can tap into our wealth knowledge regarding the fundamentals and engineering of machine design.

Gulf States Saw & Machine Co. offers the best solution for organizing and storing sheet metal safely and efficiently.

The success of manufacturing projects depends on effective management.

We sell only the highest quality metal fabrication machinery.

We can provide customers with build to print services for equipment, systems and assemblies.

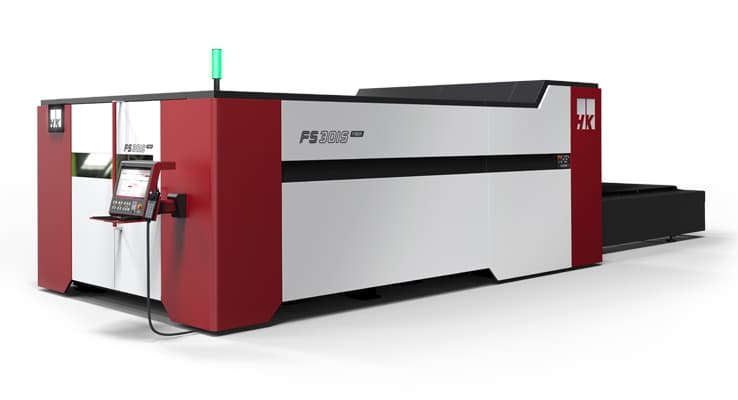

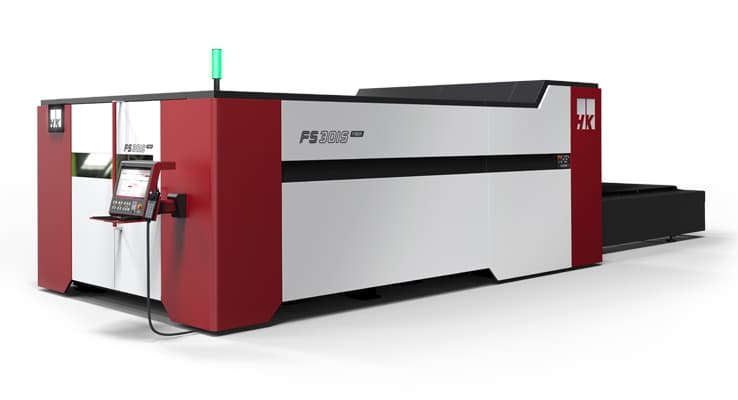

Use one of our Fiber laser systems and you can forget about back reflections that could damage your laser cutter. These fiber laser machines are more cost-effective and require less maintenance.

Equipment used in the health care sector must meet the highest standards. GSS Machinery can be trusted as a manufacturing partner.

Are you planning to quote your next vacuum tube project? Get our complete vacuum chamber buying and purchasing guide to help you avoid common pitfalls.

Gulf States Saw & Machine Co. has innovative solutions as well as competitive pricing to meet your tooling needs.

GSS Machinery specializes in complex electromechanical systems, including special machinery and custom process equipment.

GSS Machinery, with its proven expertise and skills, is your best resource for automation engineering.

Testimonial - Gulf States Saw & Machine Co. is one of the most hardworking sales reps that I have ever encountered. They answered all of my technical questions, from the simplest to most difficult. They are involved in every stage of the machinery sourcing/buying process, from initial research, implementation, and support after the sale. The Precision Fab team has always made me feel 100% confident.

We are specialists in the design, fabrication and maintenance of custom machinery used in the manufacture of sterile product in aseptic environments.

'The effect that powerful lasers have on actual flesh varies both with the wavelength, or color, of the light and the duration of the pulses that they produce,' as you might expect. The real discovery of these researchers, however, is that lasers cut flesh by causing a series of overlapping micro-explosions.

Polycarbonate is an unsuitable material for laser cutting. ABS It emits cyanide gas and melts. ABS is difficult to cut with a laser cutter. It melts rather than vaporizes, and it is more likely to catch fire and leave melted gooey deposits on the vector cutting grid.

High-wattage laser cutting machines, on the other hand, are typically much more expensive than entry-level models. Some laser cutter models range in price from $4,000 to $15,000.